In some cases, additional molds may be used for specialized features or designs, especially if the tin can has unique shapes or features. The exact number of molds can also depend on factors such as the size, shape, and complexity of the tin can being produced.

The number of molds used to produce tin cans can vary depending on the specific design and production process of the manufacturer. In general, the production of tin cans involves at least two main molds: one for the body of the can and another for the lid. These molds are used in the stamping or forming process to shape the metal sheets into the desired can components.

Here's a breakdown of the typical molds used:

- Body Mold: This mold is used to shape the metal into the cylindrical form of the can body.

- Lid Mold: Another mold is used to shape the metal into the lid or cover of the can.

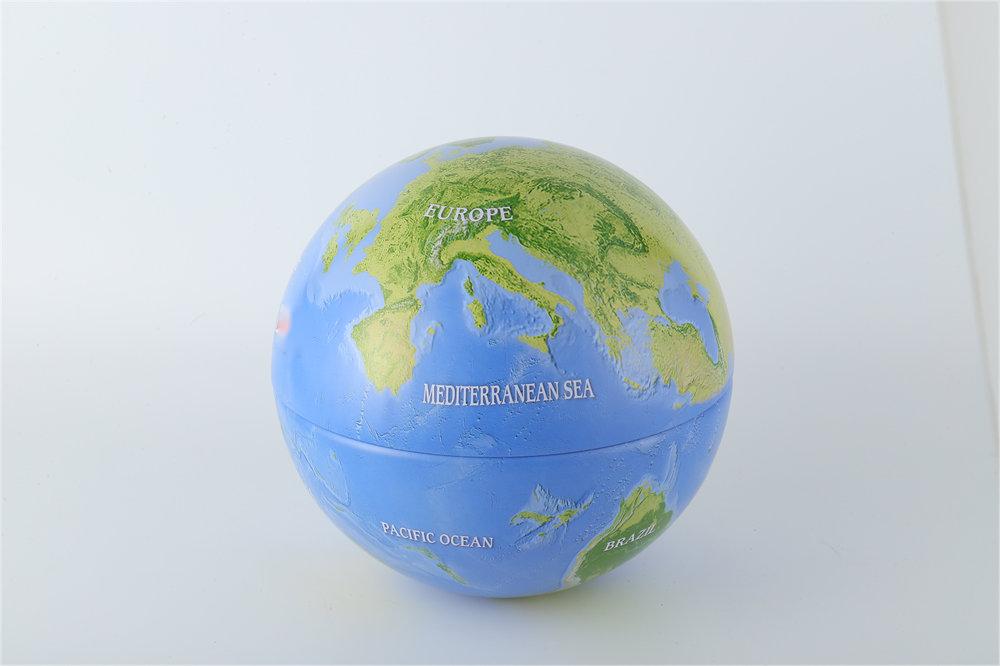

- Mold making: First, you need to design and make molds for the production of spherical cans. These molds can be used to form the tank body, or they can be used to make other parts such as LIDS.

- Material preparation: Before production, it is necessary to prepare the material used to make the ball can, usually metal plate. These metal sheets may need to be cut to specific dimensions and requirements.

- Stamping forming: Through the punching machine and other equipment, the use of molds to press the metal plate to form the basic shape of the ball can.

- Welding: The parts after stamping are welded and assembled into a complete spherical iron can. This may involve multiple welding processes, including the welding of the tank and the welding of the lid.

- Grinding and polishing: Grinding and polishing of the welded spherical iron can to improve the surface smoothness and appearance quality.

- Painting: Some ball cans may need to be painted to prevent corrosion or enhance appearance. This may include primer and top coat.

- Quality inspection: Quality inspection of the completed production of spherical iron cans to ensure that they meet the specified standards and requirements.

Learn More at : www.mj-tinbox.com